Efficiency in patisserie: Ducobu's lessons from the crisis

Debic’s culinary advisor Bruno Van Vaerenbergh paid Marc a visit in Waterloo and talked to him about the aftermath of the pandemic and the current energy crisis.

Marc Ducobu is an ambassador for Belgian chocolate and a member of Relais Desserts, an international association that brings together the hundred best pastry chefs from nineteen countries. He runs the patisserie and chocolaterie Ducobu in Waterloo.

The situation today is very different from this time last year, especially when it comes to costs. How are you coping with the rise in raw material prices?

Marc Ducobu: ‘I try to lock in my prices wherever possible. For example, I’ve negotiated a long-term fixed price for my flour with my supplier. Or I make sure that I have ingredients in stock. I bought five tonnes of sugar back in August. The price has since doubled, but I’ll be fine until after Christmas. The bigger your business gets, the better you know how to deal with it. I know I use ten tonnes of sugar a year, so I can do the maths. But you also need space to store it all – and that costs money, too. One tonne equals one pallet, so I need five pallets. And that’s just one raw material!’

Those prices have remained stable. It's mainly the rest that's affected: maintenance products, soap. Everything has gone up in price, so that sugar isn't going to make much of a difference. We've raised the prices in the ship now, otherwise we wouldn't be able to survive.'

And what about your energy costs?

‘We’re on a fixed contract until 2025, so we’re safe until then. We were fortunate enough to secure that contract last year, and we’re profiting from that now. But there are bakers with gas ovens who have seen their bills quadruple or even quintuple. The situation is different in each country, of course. Pastry chefs in France, for example, also have a fuel problem. That’s not affected us in Belgium so far, although the outlook isn’t great. The two pandemic years were actually quite good for bakers, pastry chefs and butchers. But now? I’m not so sure.’

Have you noticed the impact of the crisis on your customers?

‘We have a high volume but relatively low prices. I think our sector will survive. It’s different in a restaurant, where two people now pay more than a hundred euros for a meal. Baguettes and pastry on Sundays should still be manageable for consumers.'

‘I have good staff, so I have no complaints there. But during the pandemic, they had to contend with a high workload, long hours and a lot of pressure. So we decided to close the shop on Mondays and Tuesdays. Now I have a team that works from Tuesday to Saturday and a team that works on Sundays.' ‘Some bakers are struggling to find staff. But I try to network, give interviews and demonstrations, chair juries, take courses: it all helps. Social media also plays a role. We have almost 90,000 followers, so if I’m looking for someone to join us, I usually find them quickly. And of course, being a member of Relais Desserts also comes in handy when we’re looking for a chocolatier.’

Do you use convenience products to reduce the pressure on staff, or do you make everything yourselves from A to Z?

‘I work with both blocks and slices of butter. Slices for lamination and blocks for the rest of the preparations. And of course we also have equipment to help us, such as sprayers and dosing machines.’

As a member of Relais Desserts, are you allowed to use convenience products?

‘Yes, within Relais Desserts everyone does things their own way. The Dutch work differently from the Belgians and the Belgians work differently from the French. It’s more about the philosophy, being able to share, give advice, exchange ideas with colleagues. But above all, it’s about quality, from the product to the packaging.’

What else do you do to improve efficiency and reduce costs?

‘I’m curious by nature. When the price of electricity goes up, I try to find a solution like everyone else. For example, my electrician tightens the fuses every year; they get loose after a while because we turn the equipment on and off a lot. It doesn’t make a huge difference, but all those little things add up. For example, we also save baking paper if it’s still clean.’

As owner and entrepreneur, do you spend more time in the office than in the bakery?

‘I prefer to be in the studio rather than at my desk. If I want to know the cost price of a cake, I’d rather ask someone else than look it up myself. I think that’s quicker than looking it up myself on my computer. There are 22 people working here today, and I was the third to arrive this morning. That’s also a strength. I’ve worked in bakeries where the boss didn’t turn up until eight in the morning, and the staff often just messed around or weren’t very focused on production. I prefer to see myself as the captain of the game, rather than being absent and sitting at my desk.’

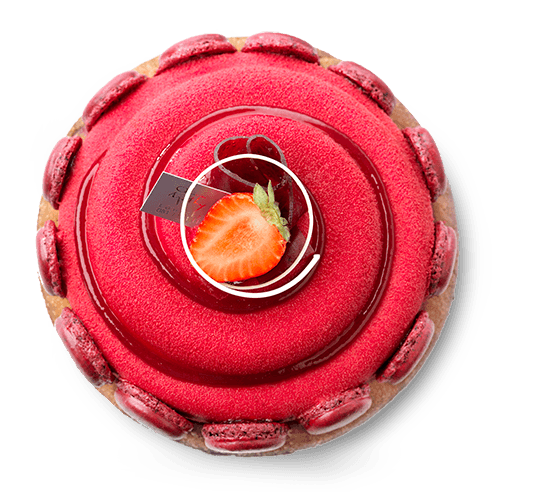

‘I still do it because it’s my passion. We’ve been in business for nineteen years and we intend to continue. More and more twenty-somethings are specializing in one product, like eclairs or cupcakes. But you can’t do that forever. The fact that we make a lot ourselves is our weakness, but it’s also our strength. I devote a lot of time and attention to St. Nicholas, Christmas, New Year, Epiphany, Valentine’s Day and Easter. In January, we make almost five thousand Epiphany tarts for one shop, and on 2 February last year we baked eight hundred pancakes. And of course, we’re always trying to improve. For example, I think about the revenue and cost price every step of the way. A kilo of almonds? My waste containers? The window cleaner? I know how much everything costs, it’s always on my mind.’

Drawing on that experience and knowledge, have you made any adjustments to your range?

‘We used to make Belgian cougnous weighing 150, 350 and 400 grams and Epiphany tarts for four, five, six and fifteen people. But we’ve stopped doing that. Now we make one size of cougnou, one size of Epiphany tart and, since last December, only one size of Christmas log. We make four different kinds, but they all fit in the same box. We used to have three different sizes and always ended up with packaging leftover. That all adds up. And, of course, it saves not only on packaging but also on preparation. If you only make one size of cake, the baking time is always the same. We also make fewer mistakes in the shop because the price is always the same. And we certainly don’t sell less than before!’

In this article, top chefs talk about their vision of a successful team.

Discover more